-

-

There are 1433 products.

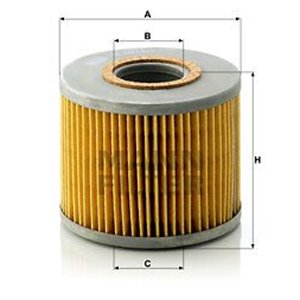

Because of its complex composition, the engine oil itself becomes contaminated with various impurities when the engine is actively running - an oil that is not up to the job. Therefore, an oil filter is needed to improve engine performance.

What the filter is for

The proper functioning of your car requires high-quality lubrication of all parts with filtered and cleaned oil. When the engine is running, all parts, including lubricated parts, come into contact with each other, which inevitably contaminates the composition of the solution.

Modern technology allows 95% of particles, soot and other contaminants to be filtered out of the oil. The oil plays an essential role in the proper functioning of the engine system and it is important that it remains in the main mixture.

When the first cars were introduced, engineers agreed that vehicles needed a cleaning device. Thanks to this innovation, oil life has increased tenfold and engine performance has multiplied. Full flow cleaning increases engine oil life and improves engine durability.

Oil filters - types and construction

Filter types do not affect full flow performance as all oil is cleaned during the process. There are different types of filtration systems:

1. There are two types of oil filters:

- Mechanical types;

- Mechanical: can be replaceable or interchangeable.

2. Gravity (slurry tanks).

3. centrifugal force.

4. Magnetic.

Filters have three basic cleaning stages: fine, medium and coarse. Usually, a vehicle has one filter to trap the different types of particles. Trucks have coarse filters - around 70 micrometres.

To screen out coarse particles, large vehicles are fitted with magnetic filters that can collect metal particles scraped off by friction. If the element becomes dirty, it can be cleaned by wiping it with a cloth.

Oil filter composition:

- Cylindrical body;

- A cylindrical filter element with a cylindrical body and a cover mounted on the bottom with inlet and outlet openings;

- filter material (paper, cloth, felt) impregnated with a special mixture;

- a valve to maintain the pressure at the required level;

- Valve to keep the oil in the engine and the piping after shutdown;

- a drain valve;

- a pressure spring.

Operational characteristics of the components of the purification system:

1. oil is fed to the filter through openings in the housing. When it enters the space between the housing and the cover, it is sent to the cleaning sector and flows out already cleaned. The body is made of high-strength alloys because it is subjected to a relatively high force of ~10 amperes.

The valve, which is the most important part of the filtration system, is usually made of a special raw material impregnated with a prepared liquid. The special shape resembling an accordion, which is also twisted into a spiral, allows the entire volume to be covered. The metal rings protect the body from compression and deformation, thus preserving the cylindrical shape.

3. A secure spring valve protects the vehicle from oil drying out - when the oil is thick, as it often is in winter. A safety spring valve prevents engine parts from drying out and the engine from failing, which can lead to wear in the future.

4. Inside the filter is a rubber ring-like element covering the intake opening, which is designed to retain the lubricant even after the engine has been switched off. When the oil, and therefore the filter, needs to be changed, there may be residue inside the filter which can leak out - the filter is fitted with a check valve to prevent leakage.

Use of oil filters

Vehicle and engine manufacturers provide a list of approved filters recommended for safe use. It is recommended to use the spare parts mentioned in this list, as they are designed for both permissible loads and oil flushing depth. Do not select a filter based on the threads or dimensions of the parts, as use with the wrong load and inadequately cleaned oil will result in wear or damage to the structure.

The machine's instruction manual indicates the recommended frequency of replacement of internal parts. Replacement is often done in conjunction with an oil change, at approximately the next 10-20 km of driving. For scheduled replacement of car parts, filters can be selected from the filter range in the dedicated section of our website. This protects the engine from rapid wear.